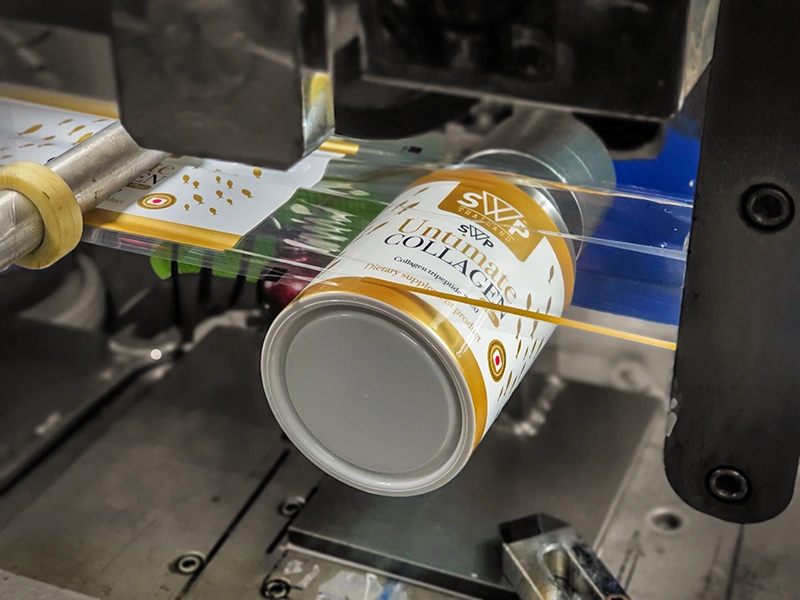

Heat transfer is a printing process that transfers images using heat. It begins by printing the image onto a plastic film, which is then pressed onto the surface of the packaging using heat and pressure. This transfers the ink seamlessly onto the surface, creating a smooth, integrated finish. The result is high-resolution, vibrant prints with exceptional accuracy and strong adhesion that won’t peel off, unlike sticker labels. This printing system not only enhances the aesthetic appeal but also provides excellent durability.

Another key advantage is its ability to transfer images onto various materials, such as different types of plastics, glass, metal, and more. It can also print on objects with different shapes, such as cylinders, cones, or curved surfaces. Heat transfer is commonly used in packaging for a wide range of products, such as paint buckets, drinking glasses, baby bottles, and stationery.